Product Engineering - Engineering Change Management

Table of Contents

- Product Engineering - Engineering Change Management

Engineering Change Management introduction

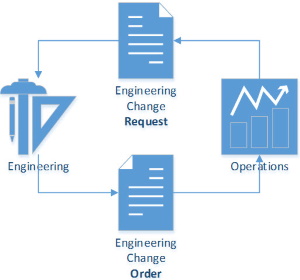

Engineering Change Management for Dynamics 365 Business Central supports the process of requesting, planning and implementing changes to products. Its main goals are to support the processing and traceability of the changes from the perspective of an ERP system. The functionality will achieve that by structuring the communication around changes between operations and engineering.

Engineering Change Management has the following business goals:

- Leaner process: by using lifecycles and workflows the process is automated with built-in checks to avoid "black boxes". Conditions and action handlers in the lifecycle do the heavy lifting to assure data consistency.

- Reduce cycle time: by sending engineering change requests (ECR) to engineering and engineering replying on these ECR's updates can be processed immediately as pre-approved.

- Eliminate errors: the lifecycle conditions validate each step for completeness of data. Automating the exporting and importing of data avoids re-typing and thus reduces the typing errors.

- Improve communication: automating the process with automatic notifications makes the process paper-free while improving the communication.

Note: In order to achieve these goals the Engineering Change process has to be carefully designed with the customer. STAEDEAN ECM offers the components to implement such a process in Dynamics 365 Business Central.

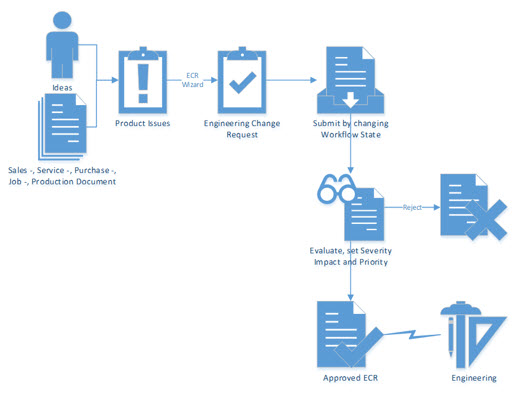

The importance of a well-structured process is in the fact that every idea around a product has the potential to improve that product and make it a better fit for customers. So whenever the product is discussed in the operation: when taking in a sales order, when the product is serviced or repaired, when purchasing from a vendor, used in a project, when manufacturing or just as a bright idea it is important that this idea is recorded to be evaluated later on.

In a structured system patterns become visible showing similar requests for the same item based on which Product Engineering can set priorities. Since we are within ERP the impact of a change can be evaluated by reporting the value of inventory, purchases, customer commitments though sales orders and projects. Based on this information a well-informed decision can be made to approve or reject a request. Approval means an assignment for the engineering department. When engineering is using a Product Lifecycle Management system the ECR?s are electronically submitted.

Implementing engineering changes also must be a structured and efficient process to quickly identify the changes and properly implement the product changes as well as making its effects on bills of material and routings visible. With detailed information on the changes the product?s stakeholders in the organization can be informed to act accordingly like informing vendors and customers.

Engineering Change Requests (ECR)

An ECR can be created with the help of a wizard from a number of source documents as well as directly as just a bright idea. When created the ECR can be completed with comments, documents and pictures.

The ECR is supported by a document approval workflow which can be installed from a workflow template. When approved the status of the ECR is set to Processed. This status is used to trigger a change log event in a connectivity studio pipeline to export the ECR to engineering. The combination of Severity and Impact determines the priority for the ECR, for example a Critical severity in combination with a High impact requires immediate attention of management and engineering.

Engineering Change Order (ECO)

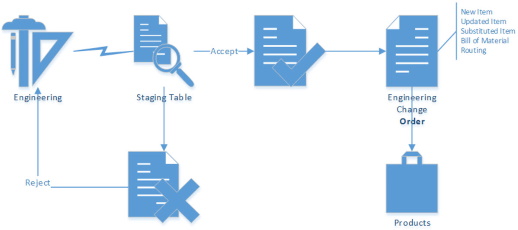

The ECO is created to install the change in the database. The updates from engineering are received as a file in the ECO staging table from where they can be reviewed. The staging table distinguishes between Items, Bills of Material and Routings. The import will validate the received information and mark the records as New, Updated and Substituted.

Based on information in the staging table fact box the user can either Accept or Reject the record. In other words records in the staging table are created through import and removed through accepting or rejecting but cannot be deleted.

An ECO is created from an Accepted record in the staging table, registering the ECO will install the change:

- New - a new item, bill of material or routing is created.

- Update - an existing item, bill of material or routing is created, the user is able to compare the existing and the new record before registering the ECO

- Substitute - a record is created in the item substitution table, when substituted with a new item the new item has to be created first. A new version of a BOM or Routing is created

Once registered the ECO is archived. The actual implementation of the change, like updating purchase orders with vendors is handled by the ECO.

Optionally, the installation or rejection of a change is confirmed back to engineering.

Batch Process to set Initial Revision

From the Role Center Actions > Manage a Batch Process is available with which the Revision No. - Description and Effective Date for Items, Production BOMs, Routings and Production Components can be set. In the filters select an item or a range of items. Optionally attach a document to be linked in the items Attachment fact box. Note that a Revision No. will only be visible on or after the Effective Date.

From the Item Card > Action > Revision Codes a list of Revision Codes can be shown. The same applies to Production BOMs and Routings.

Connector

Connectors for Engineering Change Management are based on STAEDEAN Business Integration Solutions (BIS) Connectivity Studio (CS). With CS a connector can be created, maintained and managed from the Business Central user interface. Connectors can be bi-directional, a-synchronous based an exchange of xml files or synchronous based on web services in either a pull or push scenario. In this Design Detail more information.

Engineering Change Notification (ECN)

To inform users about Engineering the following information is available:

Item Details ECR factbox

Is available on the item card and shows:

- The current Revision Code of the item.

- Note that a Revision code is only shown on or after the effective date

- The, pending, Engineering Change Requests per status.

- The Engineering Revisions (ECO) which contain the history of the implemented changes.

Production BOM Details ECR factbox

Is available in the production BOM card and shows the same information as the Item Details ECR factbox.

Notes

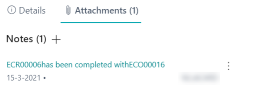

When an ECR is created from a source document (like a service order) a Note will be attached to that service order when the ECR is completed by a Engineering Change Order (ECO). These notes appear in the folowing pages based on the source type in the ECR:

| ECR Source Type | Page |

|---|---|

| Sales | Sales Order |

| Purchase | Purchase Order |

| Service | Service Order |

| Project | Project card |

| Production Order | Production Order |

| Idea | Engineering Change Request |

| Quality | Registered Measurement (Only when ECM is installed in combination QM. Request the page extension from STAEDEAN) |

| Assembly | Assembly Order |

This Note informs the user that ECR00006 has been completed with ECO00016

Notifications

When New Revision available is set in My Notifications a notification ("New Revision Code exists for Item No. ") will appear in the source document when a newer revision of the item exists at the specified date. These notifications are set for for the following entities and based on the dates as indicated:

| Entity | Date |

|---|---|

| Sales Order Line | Planned Shipment Date |

| Purchase Order Line | Planned Receipt Date |

| Service Order Line | Planned Delivery Date |

| Job Planning Line | Planning Date |

| Production Order | Due Date |

| Assembly Order | Due Date |

Note: Below a Sales Order example:

| Document | Date | Revision |

|---|---|---|

| 01-03-2021 - Archived Engineering Change Order | Effective date: 01-03-2021 | A |

| 05-03-2021 - Sales Order | Planned shipment date: 15-03-2021 | A |

| 10-03-2021 - Archived Engineering Change Order | Effective date: 10-03-2021 | B |

In this scenario the notification will pop-up when the sales order is opened after 10-03-2021. Use the Update action to update the Source Document to the new Revision Code.

See also

Tasks

- How To : Setup Engineering Change Management

- How To : Setup ECM Connections

- How To : Create an Engineering Change Request

- How To : Process an Engineering Change Request

- How To : Submit an Engineering Change Request

- How To : Import files into the EC Staging Table

- Automated review of Engineering Change Orders

- How To : Manual Engineering Change Order

- How To : Process an Engineering Change Order

- How To : Archived ECO and Confirmation

Reference