Product Engineering - Quality Management

Design Detail : Incident Entries

Incident entries are the basis for Quality Management. An incident entry records an event that might lead to a quality measurement to determine if the incident was indeed not conforming to the standard. An Incident Entry is either created through the Create Incident Wizard or automatically when subscribed to a process.

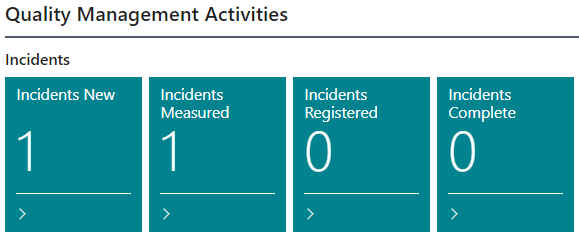

The progress of an incident is tracked through the following steps:

- Incidents New = Ad-hoc created through the wizard or system created when subscribed to a process.

- Incident Measured = The incident is investigated with a measurement and check sheet.

- Incident Registered = Investigation completed, the measurement is registered, follow-up actions planned and / or in progress.

- Closed = Follow-up completed, the incident is evaluated.

Read more about using Incidents in the 8D problem solving method

Measurements from incidents

With the Create Incident action the user, automatically, links the document (source) to the Incident, see Create Incident action.

When the program finds a, certified, Measurement Template for the same table as the source document a Measurement is automatically created. (Assuming that "Automatic create measurement" in Quality Management Setup is set to true).

When not found the Create Incident Wizard will show a message: "No Measurement Template is found for Type: %1, No.: %2, only an Incident Entry has been created." and the Incident Entry has to be handled manually.

When subscribed to a process, through a Measurement Template, the program will create a temporary incident entry for the source document and check the target templates if a template exists:

- If yes the incident entry is no longer temporary and a measurement is created.

- If not the temporary incident is deleted

Inspection type

The inspection type in the incident indicates how the incident must be checked based on the settings in the Measurement Template:

- Auto Pass = Only a data snapshot is recorded, no further inspection required.

- Paper = A checksheet must be completed, no sample to be inspected.

- Inspect = A sample has been created which needs to be inspected as per the checksheet.

See also

Product Engineering - Quality Management