ANY Process Demo: Inventory Put-Away SP

Overall Process Flow

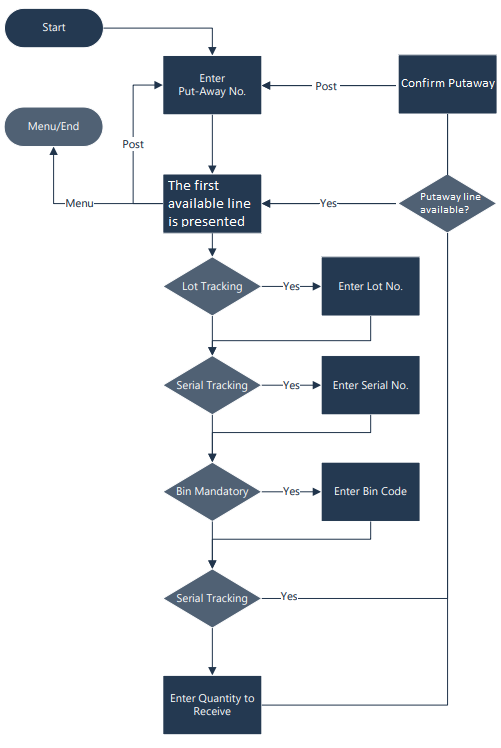

The Inventory Put-away SP process supports the goods receipt and put-away process in the warehouse based on an inventory put-away document generated beforehand in Microsoft Dynamics BC. After selection of an Inventory Put-away document, each available line to handle is presented in a sequential way. Next, if the item is tracked the Lot and/or serial number have to be entered. In case of the serial number, that is the last step for a line. Optionally, depending on the location setup, a bin has to be entered. Lastly the quantity to handle is entered. In case the quantity to handle is less than the expected quantity to put-away, the line is split, creating a new line with the quantity equal to the original outstanding quantity minus the quantity put-away. Finally, the put-away document is posted, which is reflected on the source document.

Steps

Make sure you have already set up the prerequisites for this process.

| 1. Select the Inventory Put-away SP menu button |  |

2. The next screen appears. Enter the Inventory Put-away number that was created, or use F6=Lookup to select it from a list. Press F4=OK to confirm |

|

3. The first line available for putaway is presented. You can use F8=Previous Line and F9=Next Line to move through the putaway lines |

|

4. Enter a bin code where the items will be stored. Use F6=Lookup to view a list of bins. Continue by pressing F4=OK |

|

5. Enter the Quantity to handle. (e.g. 4, make sure it’s less than the outstanding quantity) and press F4=OK |

|

| 6. By pressing OK, the Inventory Put-away line in Microsoft Dynamics BC has been updated |

- Go to the menu

Warehouse/Goods Handling/Order by Order/Inventory Put-Aways - Press Edit to view your Inventory Put-Away

- There are now 2 lines for item

70010 - The first line: The Bin Code and the Qty. To Handle are populated. The Quantity was changed from 10 to 4

- The second line: all data is copied from the first line, but the Qty. To handle is reset to 0, the Quantity is filled with the original quantity minus the Qty. to Handle of the first line

What actually is happening is the execution of the Split Line function in the mobile process while updating the Qty. to Handle of the Put-away document line.

7. The process moves to the next available line to handle. Use F9=Next Line to get item 80216-T which is lot tracked |

|

8. The next step asks for a Lot Number. Enter a new lot number and continue with F4=OK |

|

9. Confirm the suggested bin code with F4=OK to go to the next step, or select a bin code via the list with F6=Lookup |

|

10. The Quantity to handle can be entered in this step. Enter a Quantity that is less than the Quantity outstanding (e.g. 5). Confirm with F4=OK |

|

11. The process moves to the next available line to handle. Use F9=Next Line to get item 80102-T which is serial tracked. Enter a serial number and continue with F4=OK |

|

12. Enter the bin code in the following step, or select one form a list, confirm again with F4=OK |

|

| 13. No quantity to handle is requested since it’s fixed on 1 with serial tracked items. The put-away is updated in Microsoft Dynamics BC |

- Go to the menu

Warehouse/Goods Handling/Order by Order/Inventory Put-Aways - Press Edit to view your Inventory Put-Away

- Note that the line with item

80216-Thas also been split. The Quantity to Handle and tracking details are also updated.

14. The process moves to the next available line to handle. Press F7=Post to schedule the inventory put-away to be posted via the job queue |

|

| 15. The process returns to the first step, while in the background the put-away is being posted |  |

| 16. The processed lines can be seen updated in Microsoft Dynamics BC |